Drop forging

Drop Forging and hot forming

Innovative Forging Technology – Precision & Quality in Aluminium

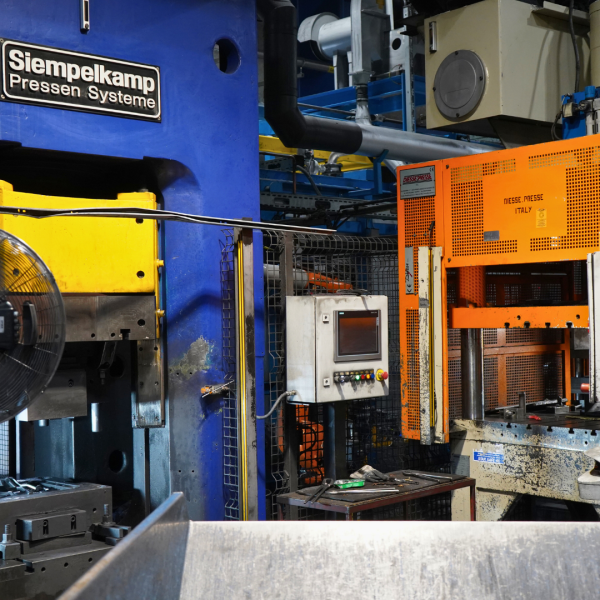

At KAISER Aluminium-Umformtechnik GmbH, we forge both standard and custom-developed aluminium alloys. Our state-of-the-art machinery enables us to process part weights ranging from just a few grams to 9 kilograms, with press forces of up to 2,500 tons. This flexibility allows us to produce a wide range of products for various industries.

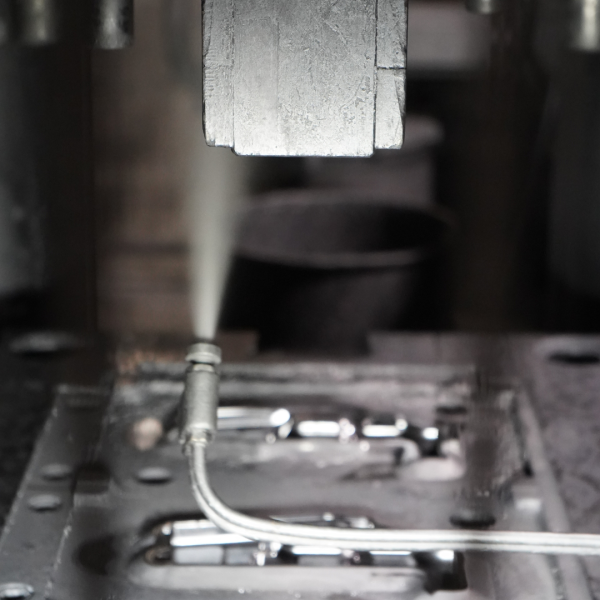

Drop forging is a material-saving forming process that enables the production of geometrically complex shapes with thin walls. At KAISER, we specialize in this process and use it to manufacture high-quality and precise aluminium products. A key advantage of Drop forging is the porosity-free and homogeneous nature of the products. The hot forming process compresses the material, leading to a uniform and solid material structure. These properties make the forged parts particularly robust and durable.

Compared to other processing methods, the forging process results in higher material strength. Drop forging optimizes the material structure, significantly increasing its strength. This is especially important for applications that must withstand high mechanical stresses.

The ideal forming temperature reduces the resistance of the material during the forming process. This facilitates the shaping of workpieces and allows for more complex shapes as well as the processing of materials with higher strength. Materials formed at ideal temperatures exhibit improved formability and ductility compared to cold forming. This allows the forming of materials that are brittle at room temperature. Additionally, when the forming process occurs at ideal temperatures, the wear on the forming tools is reduced. This contributes to a longer tool life and lowers maintenance costs.

Trust in our drop forging technology!

Let’s bring your projects to life together with our advanced drop forging technology.

Faq drop forging technology

Everything you need to know about forging technology.

Trust the drop forging technology of Kaiser aluminium forming technology and benefit From precise, robust, and durable aluminium products that meet your highest standards.

The advantages of drop forging include high dimensional accuracy and surface quality, low material usage, and the strong mechanical properties of the produced parts. With good repeatability and the ability to manufacture complex geometries, this process is particularly suited for mass production. It also offers cost-efficiency for large volumes, reduces the need for post-processing, and minimizes material waste. These benefits make drop forging ideal for producing high-strength components where precision and efficiency are crucial.

Heat-Treatable Alloys

These alloys can undergo significant strength increases through heat treatment.

2xxx Series (Aluminium-Copper Alloys): For example, 2024. These alloys offer

high strength but lower corrosion resistance. They are often used in the aerospace

industry and are well-suited for forging.

6xxx Series (Aluminium-Magnesium-Silicon Alloys): For example, 6061 and 6082.

These alloys combine good strength, corrosion resistance, and machinability, making

them popular for a variety of forging applications.

7xxx Series (Aluminium-Zinc Alloys): For example, 7075. These alloys offer the

highest strength of all aluminium alloys and are frequently used in highly stressed

structures, such as in aerospace. They are also forgeable but requ

KAISER's drop forging technology helps reduce material waste and energy consumption by ensuring efficient material use and optimized energy consumption. The precise processes minimize the need for additional machining, which in turn saves energy. Additionally, recycled materials are used, further reducing resource consumption and enhancing the sustainability of the production process.

Our drop forging technology is applied across a variety of industries, including automotive, equipment manufacturing, aerospace, medical technology, commercial vehicles, two-wheeler technology, and hunting & sporting weapons. Thanks to our ability to produce complex, highquality forged parts, we can offer cross-industry solutions.

In the aerospace industry, components must withstand high mechanical loads and meet strict safety standards. Drop forging at KAISER enables the production of aluminium parts with optimized material structure and high strength. These characteristics make the components lightweight yet robust, ideal for use in aircraft and spacecraft applications.