Construction & Toolmaking

Tool-making

Efficient Solutions in Design & Tool-making

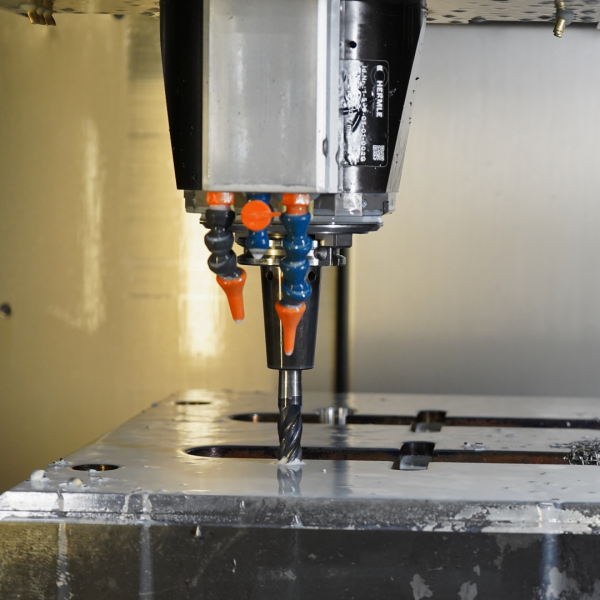

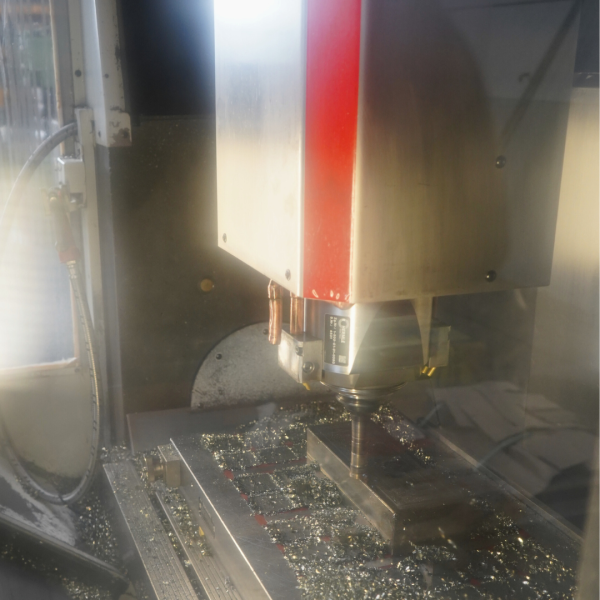

The success of KAISER Aluminium-Umformtechnik GmbH is rooted in our modern in-house toolmaking capabilities. With an advanced machinery fleet and experienced professionals, we guarantee short response times and high flexibility.

Our facilities include 5-axis CNC machining centers and state-of-the-art measuring and testing equipment. These tools enable us to produce high-precision and high-quality tools, enhancing production speed and accuracy while reducing long-term manufacturing costs.

Through customized solutions such as forming simulation and/or 3D printing, we ensure rapid adjustments to specific requirements, reduce development times, and accelerate project realization. Our durable and low-maintenance tools minimize downtime and ensure continuous production.

Rely on the expertise of KAISER Aluminium-Umformtechnik. We design and manufacture tools that perfectly meet your production needs and enhance the efficiency of your manufacturing processes.

Ready for efficiency and precision?

Discover how our customized tool solutions can revolutionize your production!

Faq tool-making

Everything you need to know about our tool-making

Rely on KAISER Aluminium-Umformtechnik's Expertise.

We design and manufacture customized tools that perfectly meet your production needs and

contribute to your success. With our extensive experience and advanced technology, we

ensure that each tool is crafted to enhance efficiency and precision in your manufacturing

processes.

Our in-house toolmaking allows us to quickly and precisely manufacture tools according to your individual requirements. This ensures short response times, high flexibility, and tailored solutions, leading to more efficient and cost-effective production.

Our equipment includes CAD/CAM software, CNC machines, milling machines, turning machines, grinding machines, EDM machines, 3D printers, precision grinding machines, and state-of-the-art measuring and testing devices. This advanced technology enables us to produce tools with the highest precision and quality, significantly improving product quality and production speed.

In-house toolmaking enhances the quality of forged parts by allowing for rapid adjustments, precise quality control, and flexible optimizations. This reduces costs and time, fosters innovation, and enables customized solutions for specific requirements, ensuring high precision and control in the production process

High-quality tools lead to cost savings by reducing the need for frequent replacements and repairs due to their durability. This minimizes maintenance costs and reduces production downtime. Additionally, high-quality tools decrease material consumption through more precise work and contribute to better product quality, which in turn lowers operational costs and improves overall profitability.

With our in-house toolmaking, we can develop customized solutions and quickly adapt to changes. This results in shorter development times and faster project implementation, saving our customers both time and costs.