Mechanical processing

Mechanical processing

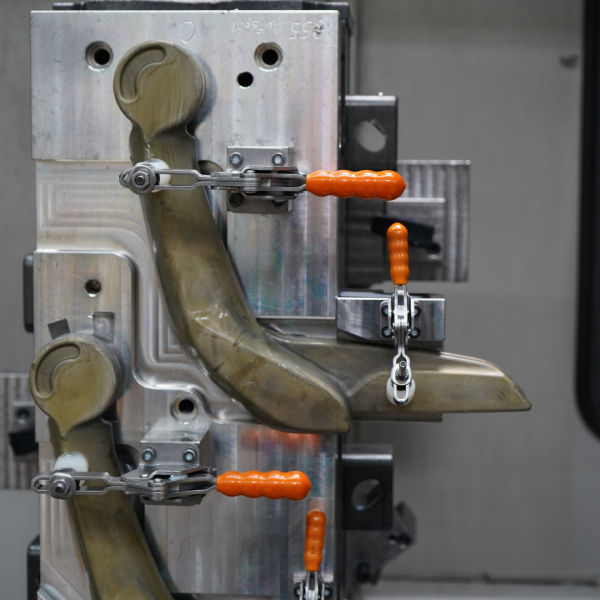

Precision Machining for the Highest Demands

We understand the importance of precise tolerances and smooth surfaces for the functionality and aesthetics of your components. Our experienced team works closely with you to fully understand and implement your specific requirements. We take pride in offering technically superior and economically efficient solutions that exceed your expectations.

Ready for precise perfection?

We work closely with you to transform your ideas into innovative and practical solutions.

Faq mechanical processing

Everything you need to know about mechanical processing.

Precision and flexibility in mechanical processing. Trust in our expertise and advanced technology to bring your projects to success.

At KAISER, we utilize state-of-the-art 4-axis and 5-axis machining centers. These advanced machines enable us to perform precise and efficient machining, even on the most complex geometries and with the most demanding tolerances

We offer a wide range of mechanical processing techniques, including milling, turning, drilling, grinding, and thread cutting. These processes allow us to achieve precise tolerances and surface qualities according to the specific requirements of our customers.

Mechanical processing after forging is crucial for several reasons:

the Forging Process

Accuracy and Precision: It ensures the necessary dimensional accuracy and

precision of the workpiece.

Surface Quality: Improves the surface finish for both functional and aesthetic purposes.

Material Removal: Excess material is removed to achieve the desired shape.

Correction of Deformations: Any deformations from the forging process are

corrected.

Functional Features: Enhances the functional characteristics of the component.

In summary, mechanical processing is essential to ensure the required precision, surface

quality, and functionality of the workpiece.

Mechanical processing reduces surface roughness and produces a smooth finish. This is especially important for visible parts or components that must interact with other parts, significantly enhancing the aesthetic quality of aluminium products.

Mechanical processing enhances the mechanical properties of forged aluminium parts in

various ways:

Dimensional Accuracy and Surface Quality: It improves the part's precision and

finish.

Defect Removal: Surface defects are eliminated.

Microstructure Adjustment: The process refines the material's microstructure.

Stress Reduction: It reduces internal stresses and increases fatigue resistance.

Overall, mechanical processing plays a vital role in optimizing the functionality, reliability, and

durability of forged aluminium parts.